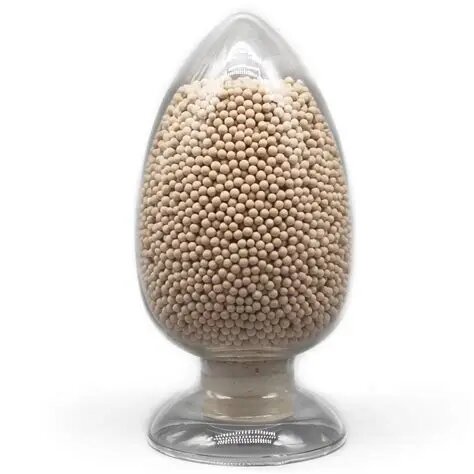

Sodium silicate is a chemical compound with the formula Na2SiO3 or (Na2O)x(SiO2)y, where x and y represent the molar ratios of sodium oxide (Na2O) to silicon dioxide (SiO2). It is commonly known as water glass or liquid glass due to its glassy appearance when dissolved in water.There are various forms of sodium silicate, but the most common and commercially available types are:1. Solid Sodium Silicate: This form appears as glassy, colorless or white beads or granules. Solid sodium silicate is often used in various industrial applications, such as detergents, soaps, cement, ceramics, and water treatment.2. Liquid Sodium Silicate: This form is a clear, thick, and viscous liquid that consists of sodium silicate dissolved in water. Liquid sodium silicate has numerous uses, including adhesives, binders, coatings, and as an ingredient in some cleaning products.The ratio of Na2O to SiO2 in sodium silicate can vary depending on the intended application and manufacturing process. Different ratios result in various properties such as viscosity, pH, and heat resistance, making sodium silicate a versatile compound with a wide range of uses in industries and various applications.