Application of Molecular Sieve in Glass

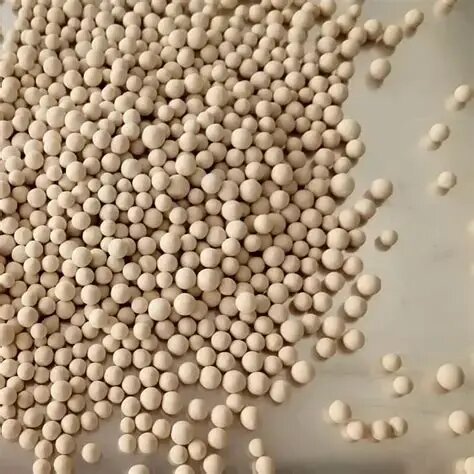

Molecular sieves are materials with highly porous structures that allow them to selectively adsorb and trap molecules based on their size and shape. They are widely used in various applications, including in the glass industry. Here are some of the key applications of molecular sieves in glass production:1. Drying agents: Molecular sieves are commonly used as desiccants or drying agents in the glass manufacturing process. Moisture can adversely affect the quality of glass, leading to defects and reducing its mechanical strength. Molecular sieves can efficiently remove moisture and other volatile compounds from raw materials, such as silica sand and other glass-forming materials, ensuring the glass produced is of high quality and free from imperfections.2. Insulating glass units (IGUs): IGUs are double or triple glazing units used in windows and doors to enhance energy efficiency by reducing heat transfer between the interior and exterior environments. Molecular sieves are incorporated into the spacer material between the glass panes. They help in absorbing and controlling any moisture that might penetrate the IGU, preventing condensation and maintaining the insulating properties of the unit.3. Argon or krypton gas retention: In some specialized glass applications, such as energy-efficient windows, argon or krypton gas is used as a fill material between the glass panes. Molecular sieves can be used to encapsulate these gases within the sealed space, preventing their leakage over time and maintaining the insulating properties of the gas-filled unit.4. Adsorbent for volatile organic compounds (VOCs): During the production of certain types of glass, volatile organic compounds may be released into the atmosphere. Molecular sieves can be employed to adsorb and capture these harmful substances, helping to meet environmental regulations and minimize air pollution in the glass manufacturing process.5. Controlling gas atmosphere in glass melting: Molecular sieves can be used to regulate the gas atmosphere in glass melting furnaces. By selectively adsorbing certain gases, they can help maintain the right composition of the atmosphere to ensure efficient melting and refining of glass materials.6. Gas purification: Molecular sieves are utilized in gas purification processes for removing impurities and moisture from various gases used in glass production, such as nitrogen, oxygen, and carbon dioxide.Overall, molecular sieves play a crucial role in the glass industry by ensuring the quality, energy efficiency, and environmental compliance of glass products. Their ability to selectively adsorb and trap specific molecules makes them valuable tools in various aspects of glass production and application.